MY series

HIGH GRADESUBMERSIBLE SEWAGE PUMPS

SERIES MY

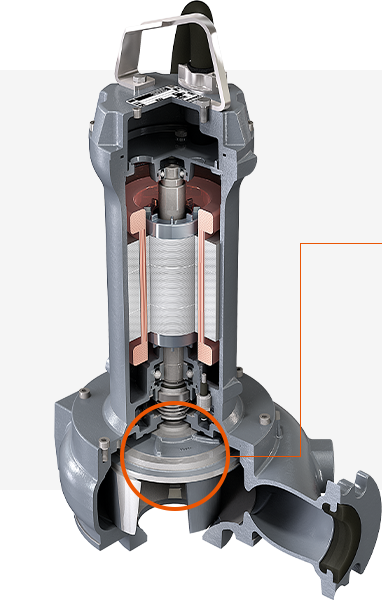

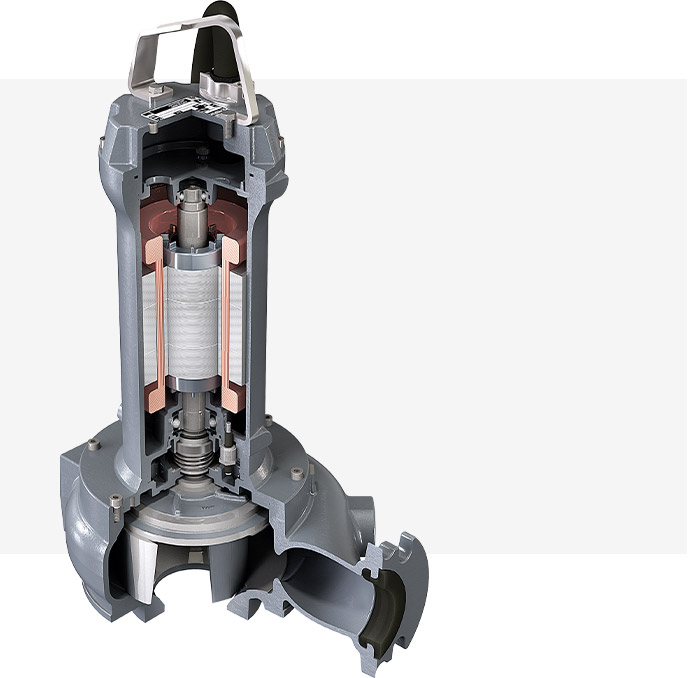

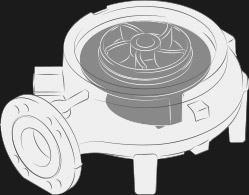

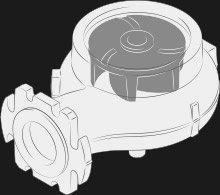

The MY-series of the TSURUMI AVANT brand features high grade submersible sewage pumps that Tsurumi makes. Designed and built with a heavy emphasis on durability and pumping efficiency, these high quality pumps are more reliable and run more stably than similar class pumps.

Moreover, to ensure users get what they are looking for, the MYseries offers 4 types of impellers (Open Channel, Vortex, Grinder and High Head) and a versatile range of specifications featuring 40 to 250 mm discharge bore diameters and 1.5 to 18.5 kW motor output specifications. A wide lineup of 2-pole motors that deliver the performance needed in high head applications is also available.

Characteristics

- Cast iron structure

- Three-phase motor from 1.5 to 18.5 kW

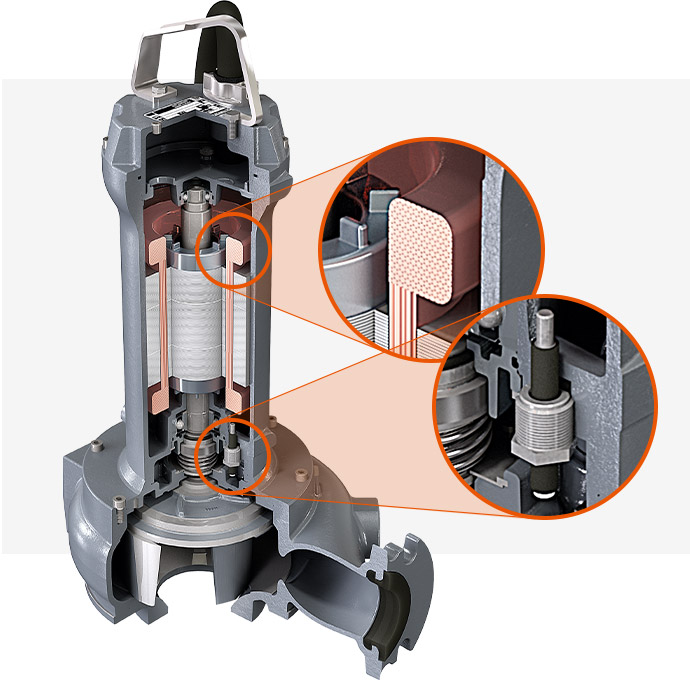

- Insulation: class H (180°C)

- Protection rating: IP68

- 50 Hz and 60 Hz versions

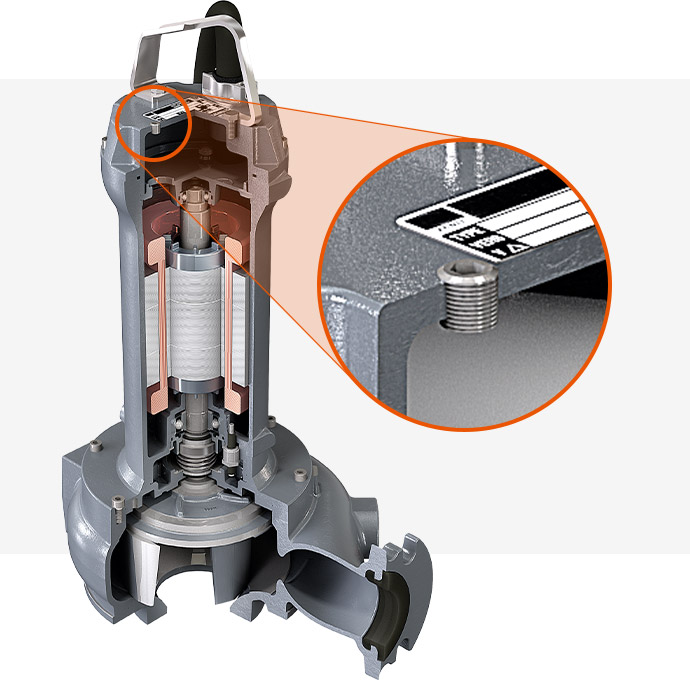

- Thermal protection devices incorporated in stator

- AISI 431 drive shaft

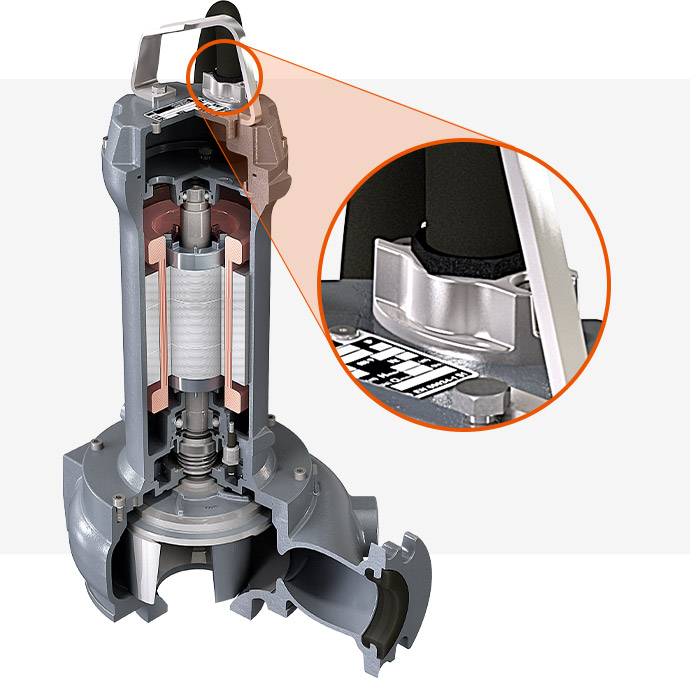

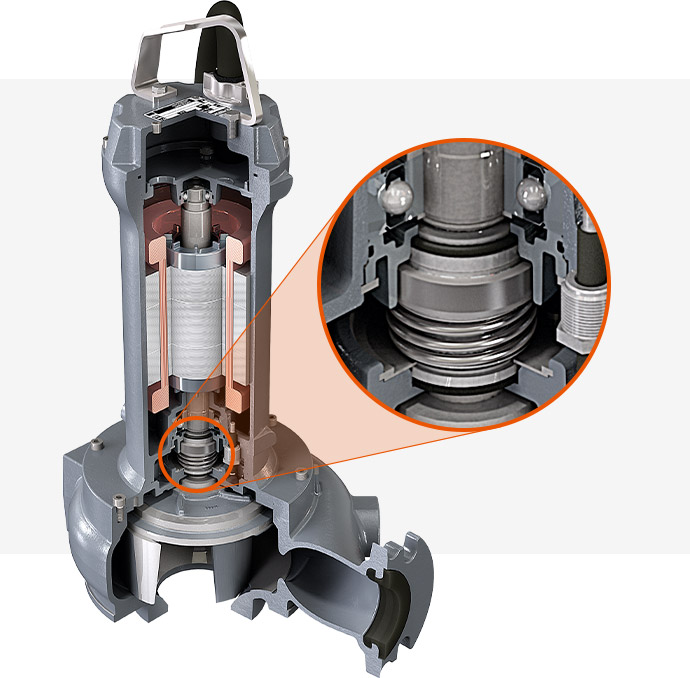

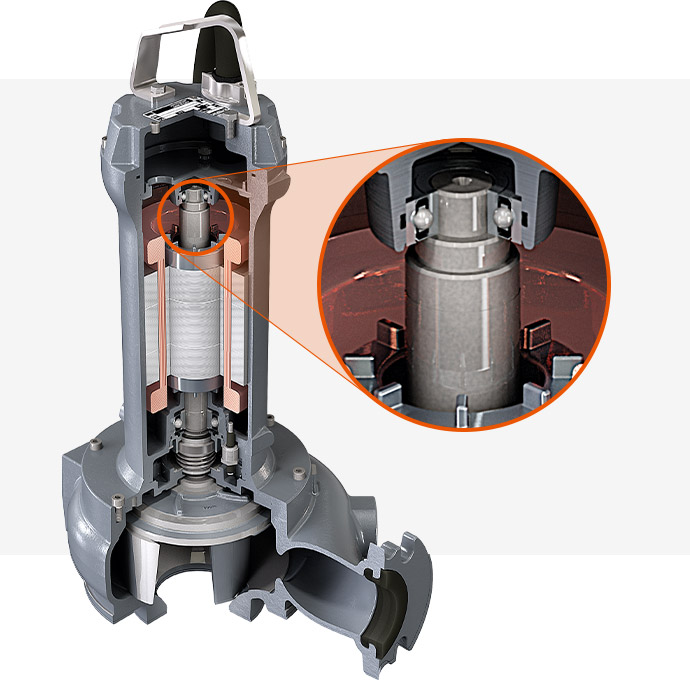

- Double silicon carbide mechanical seals in large oil chamber

- Discharge from DN40 to DN250

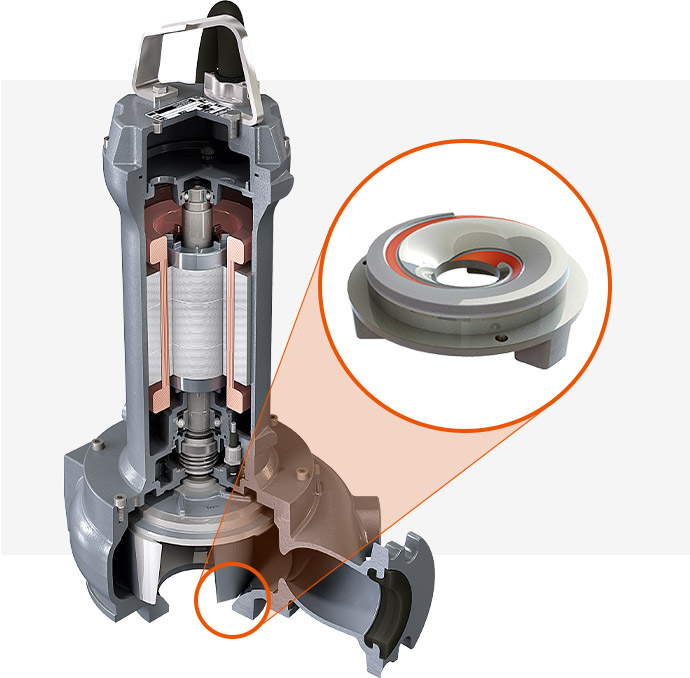

- Large free passage

Features

Overview of operating ranges

-

MYB (Open Channel)

Range characteristics

- Type of impellerOpen Channel

- Power (P2)0.37 - 18.5 kW

- Poles2 / 4 / 6

- Discharge

- VGAS 1¼" - 2"

- HDN 65 - 250

- Free passagemax 110 mm

- Max flow rate205 l/s

- Max head50 m

-

Hydraulics

- Open Channel impeller

- Large free passage

-

Suitable for

- Recirculation of industrial and process waters

- Civil lifting

- Drainage and lifting of water from first rainfall tanks

-

MYU (Vortex)

Range characteristics

- Type of impellerVortex

- Power (P2)0.37 - 15 kW

- Poles2 / 4 / 6

- Discharge

- VGAS 1½"-2½"

- HDN 65 - 150

- Free passagemax 125 mm

- Max flow rate106 l/s

- Max head24.5 m

-

Hydraulics

- Vortex impeller

- Full free passage

-

Suitable for

- Biological liquids and wastewater

- Civil and industrial lifting

- Wastewater treatment plants and livestock farms

-

MYG (Grinder)

Range characteristics

- Type of impellerGrinder

- Power (P2)0.75 - 9 kW

- Poles2

- Discharge

- V-

- HGAS 1½" - 2"

DN 40 - 100

- Free passage-

- Max flow rate8.4 l/s

- Max head53.5 m

-

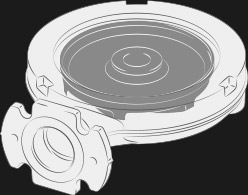

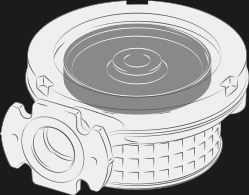

Hydraulics

- Multi-channel open impeller

- Grinding system with rotary knife

-

Suitable for

- Lifting of liquids containing fibres and filaments

- Professional and industrial applications

- Livestock farms

-

MYS (High Head)

Range characteristics

- Type of impellerHigh Head

- Power (P2)0.75 - 9 kW

- Poles2

- Discharge

- V-

- HGAS 1½" - 2"

DN 40 - DN 50

- Free passagemax 10 mm

- Max flow rate10.5 l/s

- Max head52 m

-

Hydraulics

- Multi-channel open impeller

- High manometric head

-

Suitable for

- Industrial applications and car-washes

- Clean water in fountains and water features

- Irrigation and fish farming