MMR series

PREMIUM GRADE

SUBMERSIBLE MIXERS

SUBMERSIBLE MIXERS

SERIES MMR

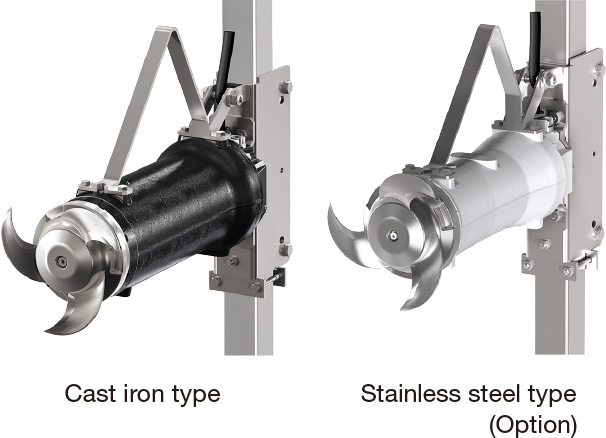

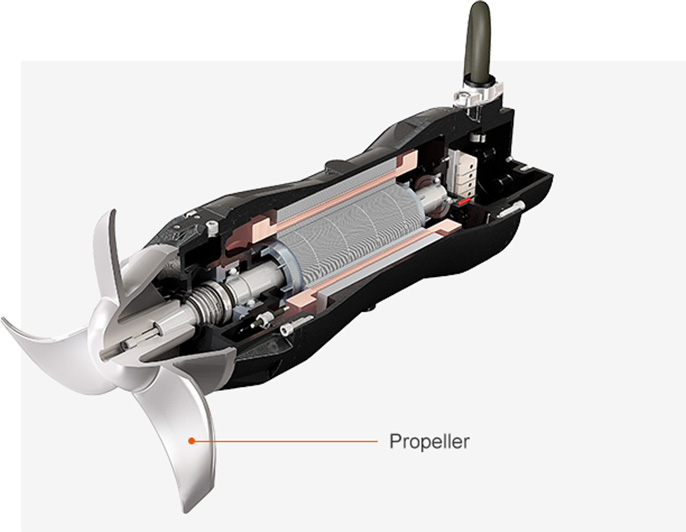

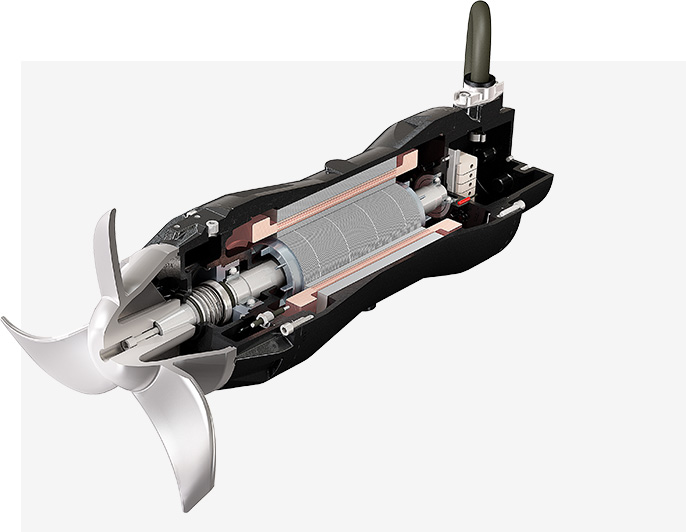

The MMR-series of the TSURUMI AVANT brand features premium grade submersible mixers with a built-in IE3 premium efficiency motor. These durable compact mixers come in standard with EN-GJL-250 cast iron body, AISI 316 stainless steel propeller, AISI 431 stainless steel shaft and Tsurumi’s typical dual inside mechanical seals with silicon carbide faces in the oil chamber. As an option, models are also available with a stainless steel body made of AISI 316. Either way, these high quality mixers guarantee users a high level of reliability and stability.

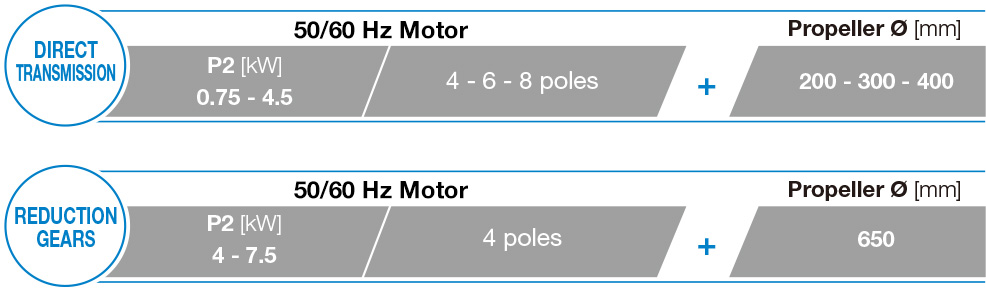

The MMR-series can be chosen from a wide lineup of propeller sizes (200 - 650 mm) and motor outputs (0.75 - 7.5 kW). Moreover, an array of accessories is available for installing the mixers anywhere inside a tank as a new installation or replacement of existing equipment.

-

- Cast iron type — Motor in efficiency class IE3

- DIRECT TRANSMISSION (200 - 300 - 400 series)

- • 4 - 6 - 8 poles motor with DIRECT TRANSMISSION

- • Motor power 0.75 - 4.5 kW

- • Propeller Ø 200 - 300 - 400 mm

- REDUCTION GEARS (650 series)

- • 4 poles motor with REDUCTION GEARS

- • Motor power 4 - 7.5 kW

- • Propeller Ø 650 mm

- Stainless steel type available (Option)

Characteristics

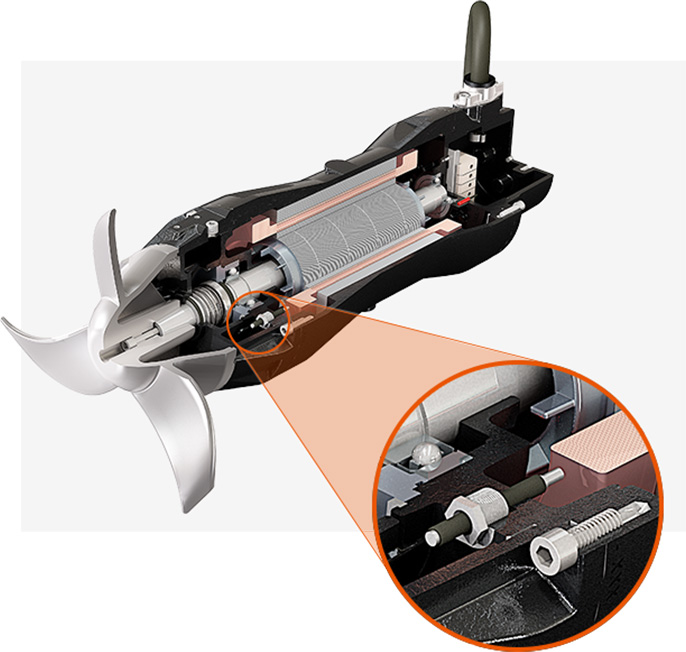

- Innovative cable gland system with cable holder. The universal thread ring-nut can be removed to fix a rigid or flexible duct to the cable gland to protect the cable from physical and mechanical stresses.

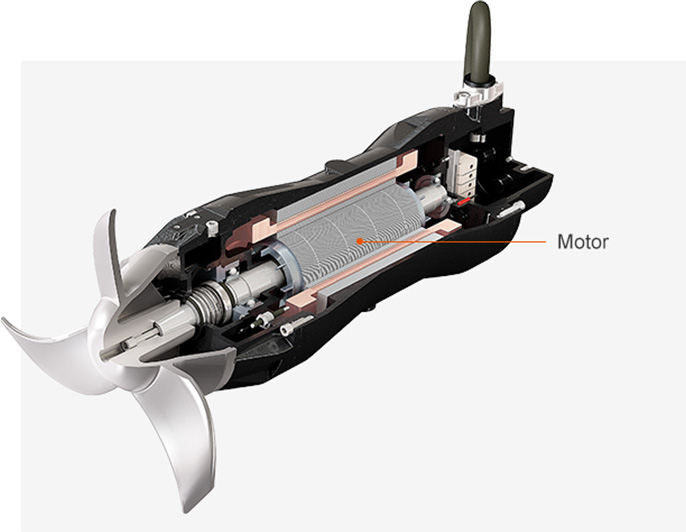

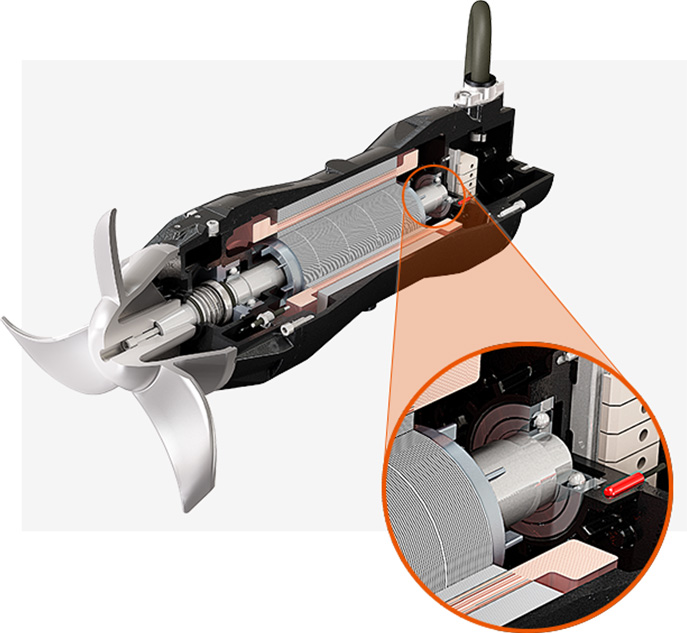

- Premium IE3 class cold-running motor for high efficiency and minimal energy use. Insulation class H (180°C).

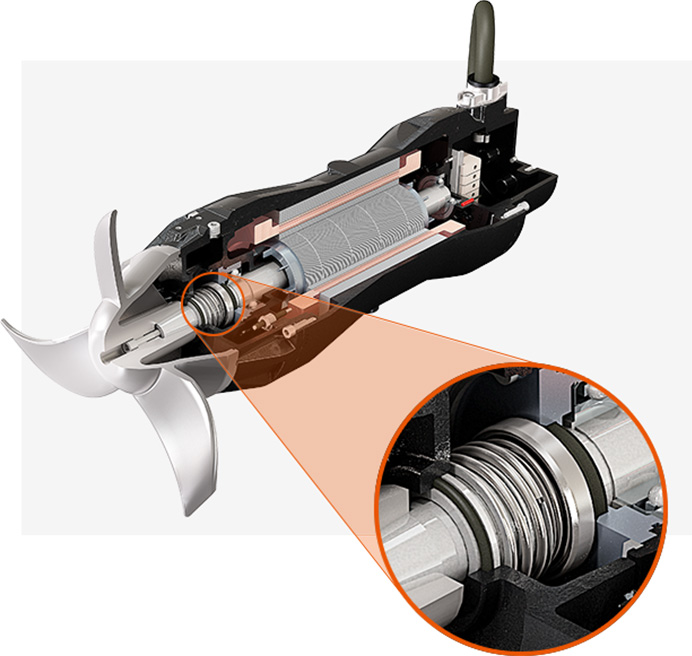

- Double silicon carbide (SiC) mechanical seals protected inside a large, inspectable oil chamber. MMR 650-series equipped with 3 mechanical seals.

- Cast AISI 316 stainless steel propeller, designed with specially shaped blades to ensure high hydraulic efficiency and prevent fouling with filaments and solids. Extra thick for ruggedness and reliability even in heavy-duty conditions.

- Water sensor detecting seepage into the mechanical seal oil chamber. The temperature sensor prevents possible damage due to overheating of the motor. Bearing temperature sensors are available on request. (other monitoring options are available for the MMR 650-series on request)

- Wide range of rugged stainless steel accessories for optimal installation in relation to the system layout and when replacing existing devices.

![REDUCTION GEARBOX [MMR 650-series]](/products/MMR-series/images/MMR-feature-REDUCTION-GEARBOX.jpg)